Air not as cold as it used to be? Energy bills climbing? The AC compressor could be the reason. Meet the system’s heart: the compressor moves refrigerant through a loop that absorbs indoor heat and sheds it outdoors. When it struggles, the rest of the system gets dragged down. In this guide, you’ll see exactly how a compressor works, which issues wreck performance, and the practical upkeep that keeps it efficient, quiet, and dependable. Wondering whether to repair or replace—or how to avoid peak-summer breakdowns? You’re in the right place.

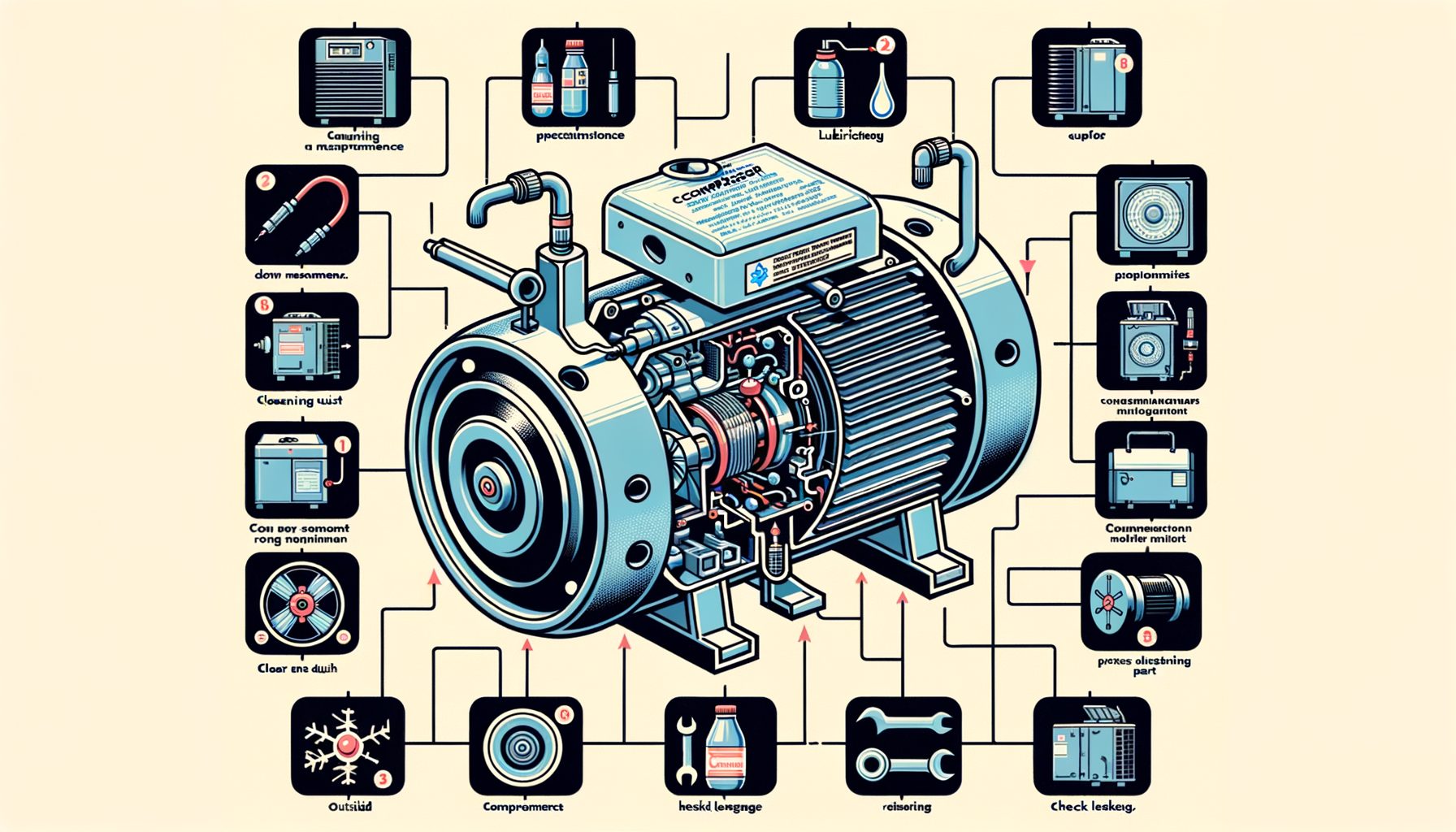

What Is an AC Compressor and Why It Matters Right Now

An AC compressor is a motor-driven pump that forces refrigerant vapor from low pressure to high pressure. The jump in pressure raises refrigerant temperature so it can release heat outdoors through the condenser coil. Without a compressor, refrigerant wouldn’t circulate at all; your air conditioner would be nothing more than a fan. That’s why technicians call it the system’s “heart.” If it fails, cooling stops immediately—and the repair bill is often the highest of any single HVAC component.

Why highlight it now? Most compressor problems begin quietly. A grimy coil drives up pressure, a weak capacitor strains the motor, and a slow refrigerant leak stretches run times. Then this: comfort slips, noise increases, and energy costs climb—especially during heat waves when the unit works hardest. Catching small issues early can add years to compressor life. For renters and homeowners alike, the payoff looks simple: fewer emergencies, steadier comfort, lower bills.

Compressors come in flavors—reciprocating, rotary, scroll, screw, and advanced variable-speed designs—but the mission stays the same: move heat efficiently. Scroll and variable-speed models dominate newer systems for better efficiency and quieter operation. Heat pumps rely on the same compressor in winter, running the cycle in reverse to bring heat indoors. What’s interesting too, understanding your compressor is a year-round topic, not just a summer concern.

Bottom line: compressor health influences everything—temperature stability, humidity control, indoor air quality, and the lifespan of the entire system. Treat it well and enjoy reliable cooling with a lower total cost of ownership.

How an AC Compressor Works: The Refrigeration Cycle in Plain English

Think of your AC as a heat mover, not a cold maker. At the center is a four-stage loop called the refrigeration cycle. Here’s the cycle in simple terms:

1) Evaporation (indoor coil): Inside the air handler, liquid refrigerant expands through a metering device (TXV or orifice) and evaporates into a low-pressure vapor. During evaporation, it absorbs heat from air passing over the coil, leaving the air cooler and drier. That’s the crisp breeze you feel at the vents.

2) Compression (outdoor compressor): The low-pressure vapor heads to the compressor, which squeezes it into a high-pressure, high-temperature vapor. Compression raises both pressure and temperature—like pumping up a bike tire, it gets hot. That hot vapor is now ready to dump heat outdoors.

3) Condensation (outdoor coil): The hot, high-pressure vapor flows through the condenser coil and releases heat to the outdoor air. As it cools, it condenses into a high-pressure liquid. A fan sweeps air across the coil to carry heat away efficiently.

4) Expansion (metering device): The high-pressure liquid is throttled through the metering device back to low pressure, cooling it dramatically. Now it returns to the indoor coil and the loop repeats.

Two details make or break compressor health: airflow and refrigerant charge. If airflow is restricted (clogged filters, blocked vents, dirty coils) or the charge is off (too much or too little refrigerant), the compressor works harder. Elevated head pressure from a dirty outdoor coil or floodback from liquid returning to the compressor due to poor superheat can slash lifespan. Technicians confirm proper charge by measuring superheat and subcooling with gauges and temperature readings, ensuring the metering device is doing its job.

Refrigerants—R-410A, R-32, R-134a, and others—differ in pressure-temperature behavior and environmental impact. Lower-GWP options are increasingly common, and handling is regulated in many countries. Heat pumps employ a reversing valve to flip the cycle in winter, pulling heat from outside and pushing it indoors. In both modes, the compressor does the heavy lifting. When it runs efficiently—supported by clean coils, correct charge, and healthy electrical components—you get comfort that’s quiet, steady, and affordable.

Common AC Compressor Problems and Early Warning Signs

Most failures leave a trail of clues weeks or months in advance. Catching them early can turn a future emergency into a quick, inexpensive fix. Watch for the big red flags and what they often mean.

Unusual noises: Clicking or buzzing usually points to electrical trouble like a failing contactor or capacitor. Grinding or rattling can mean worn bearings or loose parts—noise at the top of the outdoor unit may be the fan, not the compressor. A high-pitched squeal can signal pressure imbalance or a failing motor. Loud humming with no start often means a weak start/run capacitor or a locked rotor.

Poor cooling and long runtimes: Warm supply air, rooms that never hit setpoint, or stubborn humidity point to weak heat transfer or an incorrect charge. Dirty indoor/outdoor coils, clogged filters, blocked returns, or a failing metering device push the compressor into overtime. Over time, overheating, tripped thermal overloads, and reduced lifespan follow.

Frequent breaker trips: Electrical overloads, short circuits, winding issues, or a hard-starting compressor can trip breakers. While a tripped breaker protects the unit, repeated trips signal a deeper fault. Constant resets without diagnosis can make damage worse.

Frost or ice: Ice on the indoor coil or refrigerant lines usually indicates low airflow or low charge—both risky for compressors. Poor airflow can allow liquid refrigerant to return to the compressor; designed to compress vapor, it can be damaged by liquid slugging. Low refrigerant typically means a leak that should be found and fixed, not just topped off.

Oil stains and hissing: Oil around fittings, service ports, or coils often points to a refrigerant leak, since compressor oil travels with the refrigerant. Hissing could be a leak, a metering device noise, or normal equalization at shutdown—but continuous hissing paired with oil residue deserves attention.

| Symptom | Likely Cause | What You Can Do | Risk to Compressor |

|---|---|---|---|

| Warm air, long cycles | Dirty coils, clogged filter, low refrigerant, weak capacitor | Replace filter, clear vents/returns, clean outdoor coil, schedule a charge check | Medium–High if ignored |

| Loud humming, won’t start | Failed start/run capacitor or contactor, locked rotor | Turn off power, call a pro; do not repeatedly reset breaker | High |

| Breaker trips repeatedly | Electrical short, winding failure, seized compressor | Stop resetting; get diagnosis ASAP | High |

| Ice on lines/coil | Low airflow, low charge, metering device issue | Thaw system, replace filter, ensure airflow; schedule leak check | High if liquid floodback occurs |

| Hissing and oil stains | Refrigerant leak | Request leak test and proper repair; avoid “top-offs” | Medium–High |

Professional diagnosis matters because symptoms overlap. A technician will typically check static pressure and airflow, measure superheat/subcooling, inspect capacitors and contactors, and evaluate compressor windings. If the system is under warranty, timely service is critical; operating a failing compressor can void coverage. For safety and environmental reasons, refrigerant handling should be performed only by certified professionals; see the U.S. EPA Section 608 program or your country’s equivalent.

Key Maintenance Tips to Extend Compressor Life

Preventive care is the cheapest insurance for your compressor. The goal is to cut thermal, mechanical, and electrical stress so it doesn’t work harder than necessary.

Prioritize airflow: Replace or clean filters every 1–3 months during heavy use. Keep returns and supply vents clear. Dust around the indoor coil access area can be gently vacuumed if accessible, and professional coil cleaning should be scheduled when buildup is visible or airflow is low. Outdoors, maintain 60–90 cm (2–3 ft) of clearance around the condenser. A garden hose rinse from the inside out is usually enough; high-pressure washers bend fins and should be avoided.

Keep the charge right: Both low and high refrigerant charge strain the compressor. If cooling has dropped off, ask for a performance check with superheat/subcooling measurements—not just “add refrigerant.” If a leak is found, insist on repair and proper evacuation/charging. Well, here it is: topping off without fixing the leak wastes money and harms the environment. Learn more at Energy Saver (U.S. DOE).

Protect the electrical side: Capacitors and contactors fail far more often than compressors and are inexpensive. Replacing a weak capacitor early can prevent hard-start conditions. Wiring should be tight and free of corrosion. Consider a surge protector if storms or unstable power are common in your area.

Mind the thermostat strategy: Avoid extreme setpoint swings that cause rapid cycling. To save energy, raise cooling setpoints by 1–2°C (2–4°F) when away, and let a programmable or smart thermostat pre-cool before you return. Constant on-off toggling stresses electronics and the compressor.

Seasonal tune-ups: A yearly service before peak season can catch failing capacitors, dirty coils, incorrect charge, or airflow bottlenecks. Ask your technician to record baseline data—amps, pressures, superheat/subcooling—so trends jump out next year.

Repair versus replace: When a compressor fails in a 10–12-year-old system or one using an older refrigerant, full system replacement can be smarter than installing a new compressor in aging equipment. New variable-speed systems and high-efficiency heat pumps can slash energy use, and many regions offer rebates. Check guidance from ENERGY STAR and your local utility. A common rule of thumb: if the repair exceeds 30–40% of the cost of a new, high-efficiency system—and your unit is near end-of-life—replacement often delivers better lifetime value.

Off-season care: Keep the outdoor unit clean, block leaves and debris, and ensure drainage is clear. In rainy or coastal climates, a fresh-water rinse now and then helps fight corrosion. If you use a cover in winter, choose a breathable one that doesn’t trap moisture.

FAQ: Quick Answers About AC Compressors

How long does an AC compressor last? With proper maintenance and normal use, many residential compressors run 10–15 years. Harsh climates, poor airflow, incorrect charge, and electrical issues can shorten that span.

Can I run my AC if the compressor is failing? Risky. Overheating, breaker trips, and system contamination after a seizure are possible. If you hear loud humming, smell burning, or notice breaker trips, shut it down and call a professional.

Do I need to “top up” refrigerant every year? No. A sealed system doesn’t consume refrigerant. If the charge is low, a leak is likely and should be found and repaired before recharging.

Is compressor replacement always the best fix? Not always. A relatively new system under warranty may justify compressor replacement. For older, less efficient systems, full replacement often improves comfort, reliability, and energy costs.

What’s the difference between single-stage and variable-speed compressors? Single-stage is either on or off. Variable-speed (inverter-driven) compressors modulate output to match demand, improving comfort, humidity control, and efficiency while cutting noise and wear.

Conclusion: Keep Your AC Compressor Healthy for Reliable, Efficient Comfort

We covered what the compressor does, how it powers the refrigeration cycle, the warning signs of trouble, and the maintenance steps that protect your investment. The pattern is clear: small habits—clean filters, clear outdoor coils, correct charge, healthy electrical components—deliver big wins. Expect steadier temperatures, drier indoor air, quieter operation, and lower utility bills. Even better, those habits help you avoid the sudden breakdowns that love to arrive during the hottest week of the year.

Facing warm rooms, long runtimes, odd noises, or recurring breaker trips? Act now. Start with quick wins you can do today: change the filter, remove debris around the outdoor unit, and verify vents and returns are open. Next, schedule a professional tune-up to check airflow, superheat/subcooling, and electrical health. If your system is older or uses outdated refrigerant, ask for both repair and replacement options so you can compare costs, warranties, and efficiency gains. Rebates or incentives in many regions reduce upfront costs and speed up payback.

Your compressor doesn’t need perfect conditions; it needs consistent, thoughtful care. A little attention each season costs far less than emergency replacement. By following the guidance here, you’ll extend compressor life, handle refrigerant responsibly, and keep your home comfortable through tough weather. Make your next move now: give the system a quick visual check, set a reminder for filter changes, and book a pre-season tune-up. Comfort, savings, and peace of mind are closer than you think.

What’s one small step you’ll take today—clean the outdoor unit, change the filter, or schedule that check-up? Your future self (and your compressor) will thank you.

Sources and further reading:

U.S. Department of Energy – Central Air Conditioning

U.S. EPA – Section 608 Refrigerant Management Program

ASHRAE Handbook (Technical Resource)